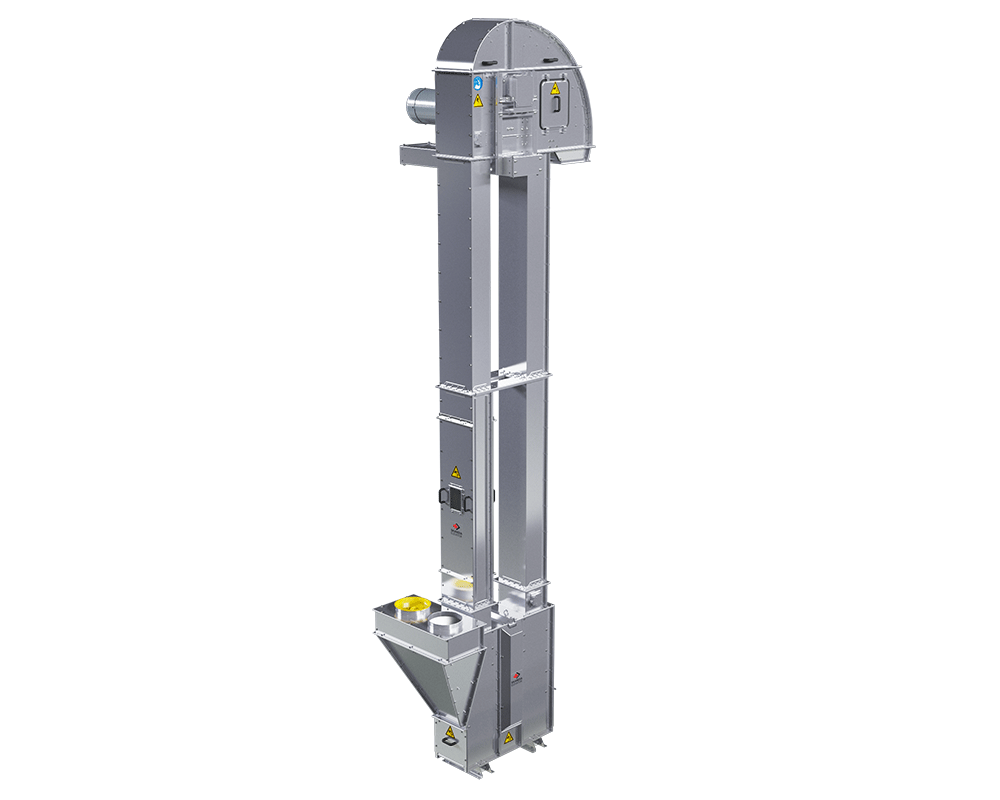

New generation 50/18, 50/23 & 63/30

For many years, Skandia Elevator has produced elevators and conveyors for more efficient grain handling. With input from our customers, and through close analysis of materials handling, we have now developed a new generation of elevators. The result is an optimised flow, less wear and simpler maintenance, while the elevators can built higher.

SIMPLER SERVICE

Great focus has been given to the design in order to simplify service and maintenance. Among other things, the elevator hood is now dividable, the inspection hatches in the legs have been made larger and the boot has two extra cleaning hatches in the form of retractable cassettes on the short sides. These smart solutions provide more convenient access, which in turn simplifies the work and reduces downtime.

MORE RELIABLE OPERATION

The general design and function of the elevators have been revised in order to provide more reliable operation. As an example, the drive wheel is fully coated with ribbed friction rubber. This new solution provides an optimised grip and prevents material from attaching between the drive wheel and belt.

SIMPLER INSTALLATION AND ADJUSTMENTS

Revising the design of the individual components has meant that the assembly and adjustments have become simpler. A fast and secure installation also means getting the operation started more quickly.

HIGHER QUALITY

In order to meet customer requirements, we have increased the dimensions, changed belt type to VLE (Very Low Elongation), and optimised the power requirement. This means that we can build higher elevators. The new VLE belt stretches considerably less and has longer service life, which significantly reduces the need for retensioning. Naturally, this saves both time and money. In order to minimise the risk of wear, we have also increased the surface area of wearing surfaces in the elevator hood and the outlet, and also added wearing surfaces on all exposed

surfaces in the elevator boot.

ELEVATOR HEAD

• The elevator hood is dividable.

• There is an inspection hatch on each side plate in the head.

• The head pulley assembly is vertically detachable.

• The adjustment ratchets for belt alignment adjustment are easily accessible.

• The bearing housings are in a more compact design, which reduces the dimensions of the mechanical structure by 30–40 mm, and reinforces the supporting structure.

• The drive wheel is fully coated with ribbed friction rubber.

• A new design of elevator hood has been developed using simulations and calculations. The design now follows the trajectory of the grain, which minimises wear to the steel plate and damage to the grain.

• All exposed surface areas are equipped with plasticwearing surfaces.

BELT AND BELT TENSIONING

• VLE belt.

• More generous belt tensioning options.

ELEVATOR LEGS

• The elevator legs have larger cross-section.

• The leg joints are made of thicker steel plate.

• The bolted joints for the leg covers are fitted in external flanges, which facilitates the assembly of various accessories.

• The service doors are larger.

OTHER ITEMS

• The power requirement has been optimised.

ELEVATOR BOOT

• Clean out hatches are fitted on all side plates, on the short sides in the form of retractable cassettes.

• The tensioning screws are easily accessible from above.

• Complete mounting for belt alignment switch.

• Complete mounting for belt and slatted pulley scraper. The mounting adjusts automatically according to tensioner wheel setting.

• All exposed surface areas are equipped with plastic wearing surfaces.

TECHNICAL INFO

| Model | 60 | 80 | 100 | 120 |

|---|---|---|---|---|

| Capacity t/h | 67 | 90 | 112 | 134 |

| Capacity m³/h | 89 | 119 | 149 | 178 |

| Nom. shaft rpm | 123 | 123 | 123 | 123 |

| Model | 150 | 200 | 250 | 300 |

|---|---|---|---|---|

| Capacity t/h | 168 | 221 | 279 | 336 |

| Capacity m³/h | 223 | 294 | 371 | 448 |

| Nom. shaft rpm | 123 | 97 | 97 | 97 |

PRODUCT LINE

H-Line is our product line for daily use, continual operations and year-round production. H-LINE is developed to fulfil the stringent requirements of the grain industry.