Laurence Kirkby Farms

Laurence Kirkby Farms’ high-tech drying

Future-proofed and automated dryer control.

For any automated process to be successful, it also needs to be simple. That’s the findings of George Strawson of Active business Partnerships who manages the 800ha Laurence Kirkby Farms, Beaumontcote, north Lincolnshire.

He and his team have enjoyed two harvests with an all-new grain store and dryer combination, with the latter being retro-fitted with Tornum Intelligent Dryer Control (IDC) for the 2021 harvest.

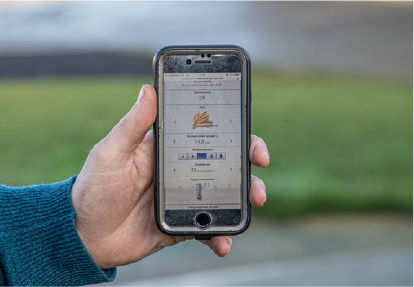

“With IDC, I have full remote monitoring and also an over-riding control of the dryer using web-based software,” he says. “We’re no longer over-drying grain, so our output is up and our costs are down.”

Laurence Kirkby Farms invested in new fixed equipment following the sale of a site where 3,500 tonnes of storage had previously been located. This 30-year old gas-powered installation included on-floor drying with stirrers, and its multiple 700 tonne spaces could lower moisture content by just two per cent/day.

“Farming close to the river Humber, we do get quite an influx of moisture across the farm – it’s great for growing crops, but challenging in summer when we don’t get very many drying days,” he says. “Anything harvested above 18% was always difficult to dry.”

He says that the old site was also two miles from Beaumontcote Farm, and required constant attention.

“If a process works well, it can save you time and money,” says George Strawson, who no longer needs to employ an extra member of harvest staff to run the arm’s dyer, thanks to plant automation.”

“I had an opportunity to centralise all our drying and storage facilities back at the main yard, improving logistics and handling, and with the right level of automation, I reasoned that I could eliminate the need for a member of staff to run the dryer,” says George. “With some careful planning, I could also utilise an existing 1,000 tonne store that offered two 500 tonne storage spaces.”

Cropping at Beaumontcote Farm comprises winter wheat, oilseed rape, spring barley, vining peas and sugar beet. With peas and beet leaving the farm at the point of harvest, crop storage requirements are relatively straightforward.

Working with grain drying specialist JW Installations who manufactures Allmet grain dryers, and civil engineering firm Timmins Engineering and Construction, the farm settled on the construction of a new 1,000 square metre store with under-floor ducting to carry pedestals. This would form the basis of a low-volume cooling and conditioning, managed by Lishman’s Barn Owl wireless grain monitoring and control, to manage warm grain as it comes off the dryer.

Without internal divisions, the building uses a single, central conveyor running through the roof space which enables the 4m high walls to provide a 3,500-tonne capacity prior to any surcharging behind the roller shutter door.

Grain is moved using 60tph conveyors, while a 40tph continuous flow Allmet grain dryer – deliberately sited between old and new stores – takes care of moisture management. It also allows grain to be distributed either to the farm’s existing 1,000 tonne store or the new 3,500 tonne store.

Keeping things moving

“We didn’t want a bottleneck at the farm yard, so the key to quick turn-arounds was having a generous intake area, where we could simply tip trailers – push-up where necessary – and go,” he says. “So we designed a 12m wide, 18m long tipping area, that would let us stockpile up to 400 tonnes of grain, at the pit.”

The intake uses a 10m conveyor to draw in what it needs to keep the dryer fed. The topography of the farm yard enabled the intake to be sited in a raised location, which Mr Strawson identified as a benefit compared with a conventional below-ground pit design.

“While we cover the conveyor with a heavy rubber mat during”

“When choosing the installation, I also wanted the ability to retro-fit the Tornum IDC, but not for the first year of use,” he says. “I wanted a season of using the new dryer and running the store manually, to get to understand the process, our crop flow and rehandling requirements. This also lets us iron-out any issues and fine-tune what we’d got, to see what works best for us.”

winter, there’s always going to be some water ingress without a roof over the intake pit,” he says. “We leave all the conveyor cleaning plates open, so the pit doesn’t get flooded. Anything that does get in, simply runs out at the lowest point.”

Longer term, he may consider adding a roof structure to the intake area when finances allow.

With the installation commissioned at the start of the 2020 harvest, Mr Strawson says that the new facilities have enabled fuel costs to be halved, contributing to a reduction in the cost of drying.

“The dryer runs for more hours than the combine, and there’s no longer any concern over the moisture content of incoming grain,” he says. “We now have plenty of capacity at our fingertips, but to make the most of that ability, we needed to upgrade with plant automation.”

Keeping costs down

According to JW Installations, over-drying by one per cent can add up to 20% more to your energy cost, while reducing the dryer’s capacity by up to 16%. It says that the Tornum Intelligent Dryer Control (IDC) continuously monitors moisture content and physically controls the speed of the dryer to achieve a precise, average moisture content of grain. This happens irrespective of external weather conditions, says the company, and uses sensors – one in the upper drying section to measure incoming moisture, and a second sensor in the cooling zone, close to the dryer’s outlet, to measure outgoing moisture. Data collected is then used by the software to manage the speed of the discharge to obtain the chosen, target moisture content.

“It’s a very effective process,” says George Strawson. “Though I’m still a little too involved, but that is my choice. I think most people will be a little cautious when it comes to automation, and you have to learn to trust the technology.”

“I choose to run the first cycle manually to get the dryer set-up and stable, then hand over to IDC,” he adds. “The discharge speed changes are then less dramatic, and the software just gets on with the job – it has certainly optimised the process.”

Peak performance

George says that every few hours he checks and recalibrates the grain dryer’s sensors, to make sure the plant is operating at its peak.

Remote data includes the number of discharges per hour, chosen moisture content, drying air temperature, and a moisture tolerance – the latter is a reaction to fluctuations with incoming moisture content, and is a reference to the intelligent control. This lets the IDC counter any effect of over-drying grain caused by sudden moisture content fluctuations, and is achieved by automatically releasing grain with a slightly higher moisture content, to average out in-store variations.

And it’s not just the drying and storage that has been upgraded – combining at Beaumontcote Farm has also been improved. Where the business once ran two older Lexions with 25ft headers, it currently operates a Lexion 770TT with a 35ft header, which is about to be upgraded again, in favour of a wider, 40ft cut enabling the farm to better manage in-field traffic.

Moving forward

A pair of 18 tonne Stewart trailers, equipped with air brakes and flotation tyres, is all that’s needed to bring cereal crops back to store.

“Our second season with the new dryer and store has let me exploit automation, and to free up more of my time,” he says. “I’m still learning, but there’s no doubt that the software works well. And if I want to over-ride the dryer, I can do it through my smartphone, tablet, or on a web browser from the farm office.”

“Drying grain is now a very easy process that no longer needs a member of staff permanently watching what’s going on,” he says. “While I can’t see the conveyors remotely, if there is a breakdown or a problem, I do get an alarm notification immediately on my phone.”

“We do have capacity to spare, both with the combine and our grain drying and storage facilities,” he says. “And that gives us capacity to grow the business. There’s now scope for a few more hectares or even some contracting for neighbours.”

With such sophistication in store, what’s next for Laurence Kirkby Farms?

“We’re currently extending the new store, by adding two, 1,000 tonne bays on the back of the building complete with more low-volume cooling and conditioning,” he says. “This enables the remaining old building to be repurposed for general storage, improving the quality and security of our storage.”

In addition, Mr Strawson says that the features and functions of the new drying and storage facilities have also delivered on paperless recording, streamlining management with store records.