Damas

DAMAS – Cleaning and Grading Machines

We offer a full range of Damas seed cleaning and grading machines—trusted by industrial producers and large-scale farmers worldwide. With over 150 years of innovation behind the brand, Damas machines are known for their precision, reliability and user-friendly design.

The Damas range includes equipment for every stage of seed processing: from pre-cleaning and fine cleaning to grading by shape, size, specific weight, and colour. Specialised machines are also available for unique processing needs.

Whether you’re upgrading existing equipment or expanding capacity, Damas delivers proven technology to help you achieve exceptional seed purity and uniformity.

You can view our Damas cleaning and grading machines below…

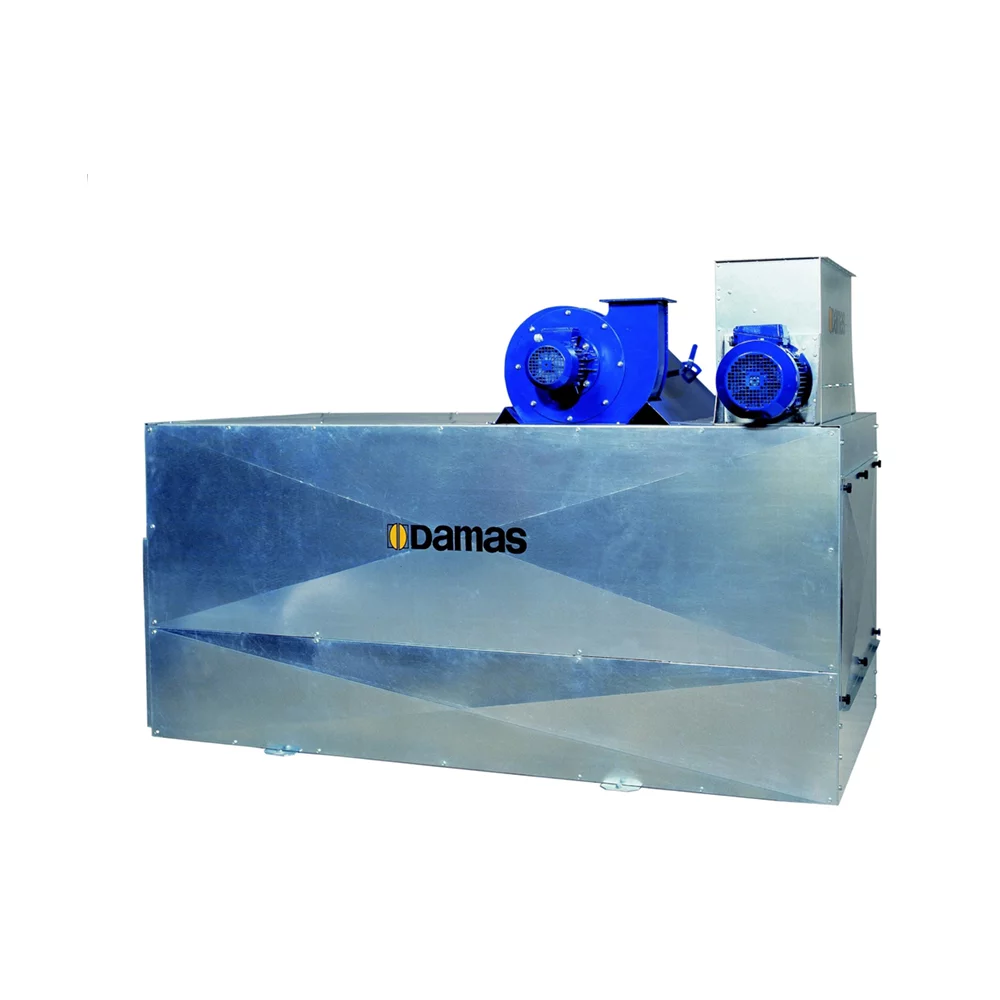

DAMAS OMEGA

The Omega cleaning machine is versatile, suitable for a wide range of cleaning and grading tasks, with optional air recirculation to accommodate local needs regarding air consumption and heat recovery.

Description:

The Omega is very flexible and can be used for all cleaning and grading tasks, from pre-cleaning to fine cleaning. The Omega can be supplied with or without air recirculation to suit local requirements on air consumption, heat recovery, etc. The air systems for pre-suction and post-suction are completely separate, which enables independent settings for easier operation combined with improved cleaning efficiency.

Features:

- Encapsulated for lower noise levels

- The screen boxes are made of hard-wearing WISAform, which is approved for use with foodstuffs

- Screen cleaning with special rubber balls

- Variable feed control as standard equipment

- Material distribution on the screen is achieved using a screw (optional on some models)

Options:

- Electronic monitoring system

DAMAS PULCO

The Pulco is an efficient aspirator that separates light and heavy crops by air, adaptable for various applications including pre-cleaning, fine cleaning, seed treatment, industrial cleaning, and malt processing.

Efficient aspirator

The Pulco efficiently separates both light and heavy crops by air.

The aspirator can be used in any plant exactly where it will be most useful. It may be for precleaning at intake, for additional air cleaning in a fine cleaning process, for cereal seed before dressing, for industrial cleaning, or for malt at outloading.

The Pulco is designed to do the best possible cleaning under all circumstances. It can also be used to fractionate by means of a separating chamber for kernels.

The Pulco is a simple, environmentally compatible construction and is easy to operate. Can be provided with remote control.

- The Pulco is self-cleaning and has a perfect flow of air because of the ideal distribution of material.

- The machine produces no vibrations and requires very little space in relation to its capacity.

- The Pulco is low-noise, requires little power and is environmentally compatible.

- A comprehensive programme of accessories in modules ensures the possibility of meeting present and future requirements.

DAMAS SIGMA

The Sigma is designed for efficient pre-cleaning and fine cleaning of grains and granular materials, featuring vertical rotary screens that offer high capacity relative to its size.

The Sigma is primarily intended for pre-cleaning of grain and other granular materials, but can also be used for fine cleaning. The SIGMA has vertical rotary screens that, thanks to the centrifugal force, provide very high capacities in relation to machine size.

Features

• Rotating vibration-free operation

• Designed for minimal demands on foundations

• Flexible installation option – easily rotatable outlet and hatch for outlet

• Fully enclosed for low noise level and a dust-free environment

• Self-adjusting roller brushes ensure effective screen cleaning

• Outlet section with highly effective aspiration unit

Options

• Electronic monitoring system

DAMAS UNISEED/DUOSEED

Damas Uniseed and Duoseed cleaning machines are designed for efficient on-farm grain grading and cleaning. They offer industrial-grade performance in a compact and cost-effective package, suitable for farms using grain for feed and sale. These machines are ideal for rapeseed, wheat, barley and maize.

Damas Uniseed and Duoseed cleaning machines are purpose-built for on-farm grain grading and cleaning, as well as small-scale industrial grain processing. These machines offer the same benefits and efficiency found in the industrial-grade Damas OMEGA cleaner/grader but in a compact and cost-effective design, making them a perfect fit for farms that utilize grain for both feed and sale.

The Damas DuoSeed, a dual Uniseed machine, optimizes space utilization in your grain processing facility. These machines come in various configurations, complete with optional feeding devices, clipper-de-awners, and pre-suction units.

Uniseed and Duoseed cleaning machines are particularly well-suited for rapeseed, wheat, barley, maize and more.

How They Operate

Uniseed and Duoseed cleaning machines are constructed with galvanized steel and employ a flatbed cleaning method. The top screen moves smoothly in a horizontal pattern, while the bottom screen follows an oblique motion. This unique motion pattern, exclusive to SKIOLD Damas cleaners, ensures highly efficient scalping on the top screen and superior material grading.

Features

• On-Farm Grain Grading: Uniseed and Duoseed machines are ideally suited for farmers who produce their own fodder or grade their grain on-site. Their compact size, ease of operation, and minimal maintenance make them an excellent choice, even for intermittent use. Additionally, waste material can be utilized in automatic stokers, minimizing waste.

• Enhanced Grain Quality: By choosing Uniseed or Duoseed for cleaning, such as rapeseed or malting barley, you can count on these machines to deliver exceptional quality, allowing you to command higher prices for your produce. These machines can also effectively remove most ergots from the grain, preserving the quality of your end product.

• Improved Germination and Reduced Costs: Well-cleaned grains germinate better, and dressing material adheres more effectively to individual grains, reducing material loss and cost.

• Higher Feed Value: When used for feed grain cleaning/grading, Uniseed and Duoseed machines produce consistently high-quality grain without unwanted contaminants, reducing dust production.

• Lower Storage Costs: Properly graded cereals or seeds in storage pose a reduced risk of degradation due to mold, fungi, bacteria, and mites. This means less concern about grain spoilage and lower expenses for subsequent drying.

• Extended Equipment Life: Well-graded cereals improve the performance and lifespan of your production equipment, optimizing your investments.

• Durable Design: Uniseed and Duoseed flatbed cleaners are built to last, featuring galvanized steel cabinets and specialized rubber balls to keep the screens clean. Minimal vibrations reduce floor or suspension stress, prolonging the life of your entire setup.

• Ease of Service and Operation: These flatbed cleaners are designed for hassle-free screen changes and straightforward day-to-day operations, making them easy to learn and master.