3U Vision Hyperion

About the 3U Vision Hyperion

The 3U Vision Hyperion machine incorporates a 4 wavelength, multi-spectral system as standard with combined RGB and IR in a single 4K sensor.

This innovative feature produces a totally aligned view. This feature is a valuable advantage when detecting defects in similar coloured products. These respond differently to infrared, such as foreign bodies, inorganic defects, etc. This single camera generates a considerable cost saving when compared to the market standard of requiring two cameras.

Specifications

New front and rear hyperspectral cameras: optional, for a selection quality never achieved before.

High resolution, multispectral, 4 wavelength cameras SWIR (1024 pixel): These cameras achieve previously unattainable results until now. They recognise polymers, selecting of shell and foreign bodies in dried fruits. They detect chemical differences not visible to the human eye.

Simultaneous use of RGB, SWIR and IR optical systems: Having up to 8 frequencies available. The market standard for this type of sorter is normally no more than 4 frequencies.

Flat spectrum LED (to reproduce the natural sunlight spectrum)

State of the art full spectrum LED, without the low light areas typical of standard white LED. This makes it possible to detect even the slightest colour variations.

Dual 15” displays Two 15” touch screens, which continuously display the key information necessary to monitor the machine effectively.

Smart, custom designed cameras, comprising hardware and software made in Italy, which incorporate an integrated elaboration and analysis system.

State of the art ejectors @ 3.2mm pitch Custom designed and specified to achieve maximum sustained velocity. Their compact design almost doubles the number of ejector valves in each chute. This feature requires less compressed air whilst increasing production capacity. This reduces the amount of good product being rejected.

RISE-UP system This feature makes the ejector bank adjustable. This allows one to locate the ejectors close to the product stream. This is almost half the distance compared to other sorters on the market. This reduces errors normally caused by the uneven fall speed of the product being sorted.

Multi wavelength LED with focusing lens This feature focuses the light specifically where it is desired. This achieves high illumination at a low consumption.

Automatic air pressure regulator The regulator automatically adjusts the pressure in the machine based on the product selected. The operator is allowed to adjust the air consumption accurately to minimise good product being rejected.

Morphological analysis of the product Extrapolating statistics of products such as average width, average height and percentage of wreckage, etc.

Automatic control and equalisation of vibrator speed This is necessary to obtain a deep and uniform stream of product in all the channels.

User friendly programming system The software has been developed to remove the need for a qualified technician to create or modify recipes.

IOT ready, totally compatible with IOT 4.0 This enables the exchange of information related to estimated throughput, estimated reject quantity, number of ejections, morphological product features, etc.

Integrated Remote-Service system In order to quickly assist the operator in real time, and avoiding the need for on-site intervention, saving the expense of a technician, regardless of your location.

Full accessibility easily removable transparent polycarbonate side panels for quick inspection, cleaning and maintenance.

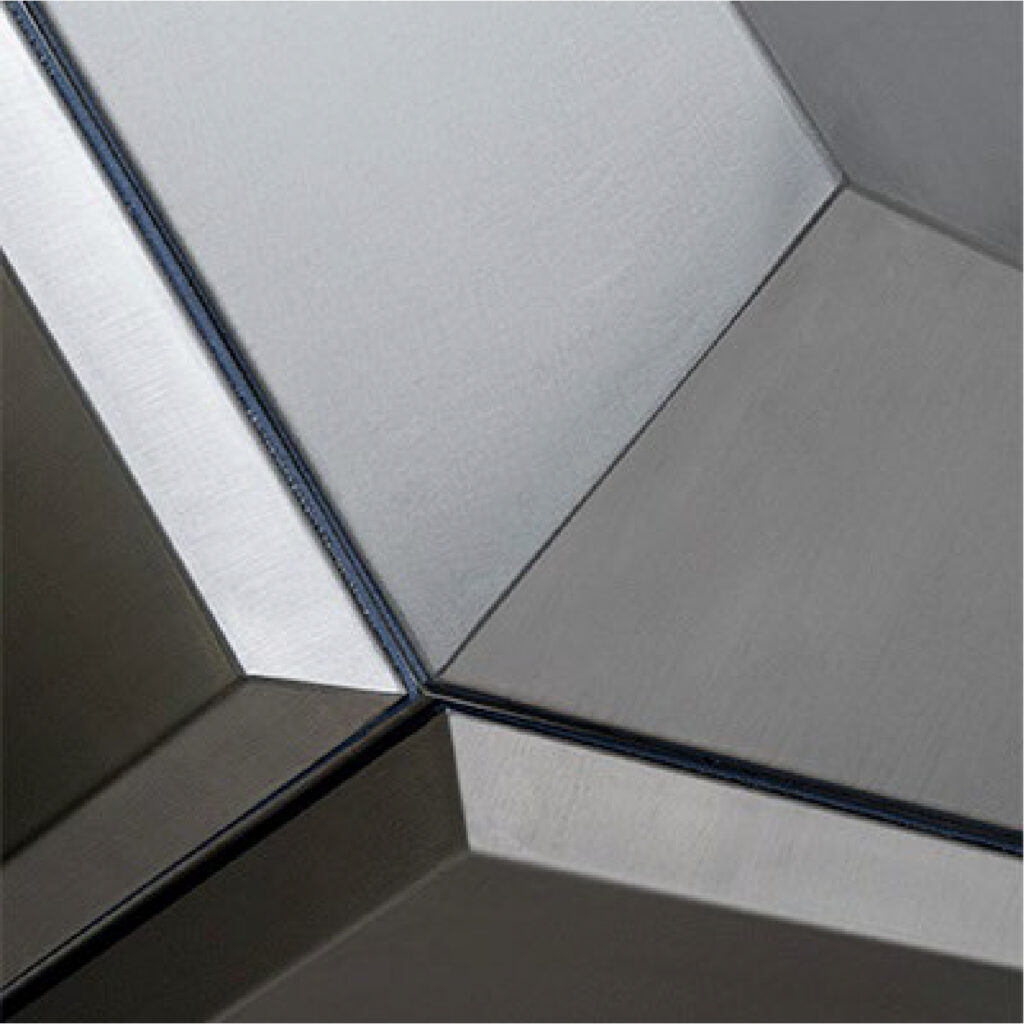

Multifunctional frame made of painted metal or stainless steel suitable for all the most demanding and critical applications.

Modular configurations allow the combined installation of different optical systems, both on front and on back to of the chute to suit all requirements.

Optional metal-detector operating simultaneously with the optical sorting.

Feeding system optimised for each specific product.

Find out more about the 3U Vision Hyperion

Vanessa Schofield, a key member of the Tornum team with extensive technical knowledge, is the primary representative for 3U Vision.

Contact Vanessa – vanessa.schofield@tornum.com / 07477 509 516