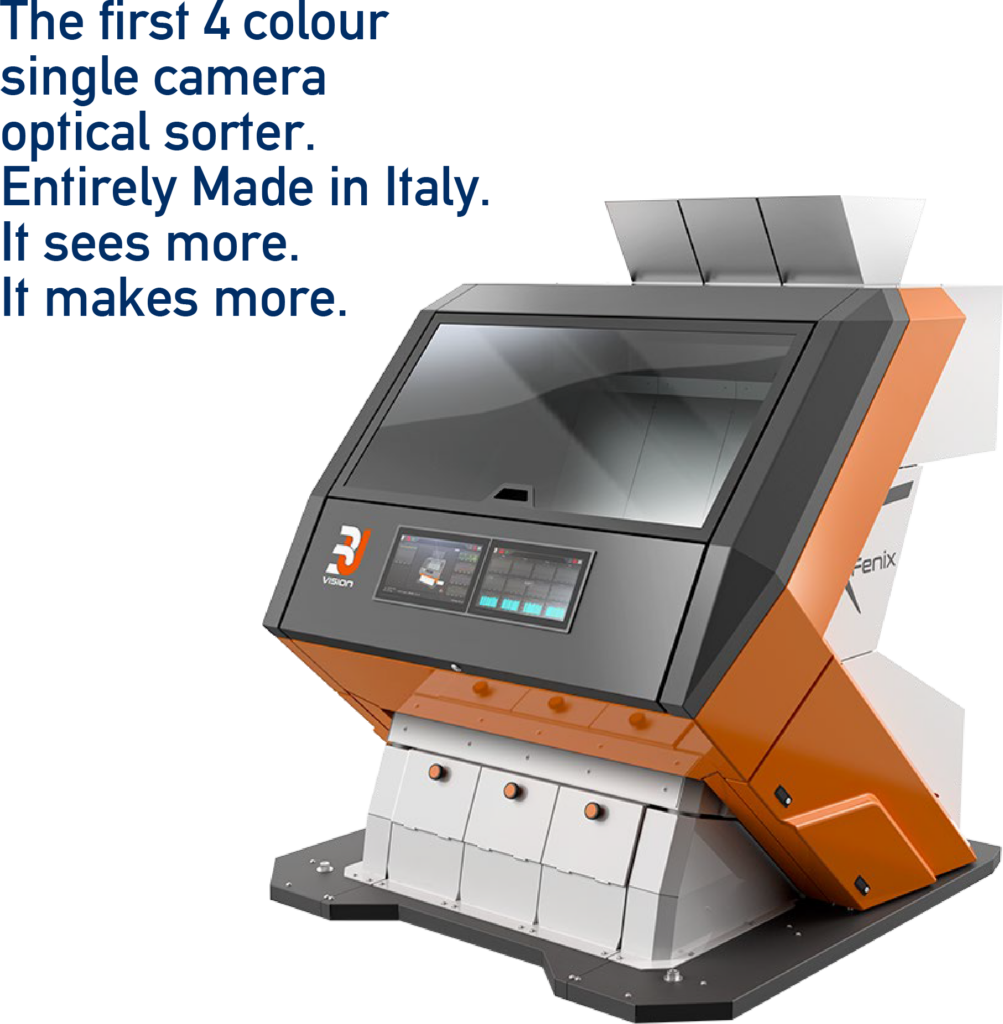

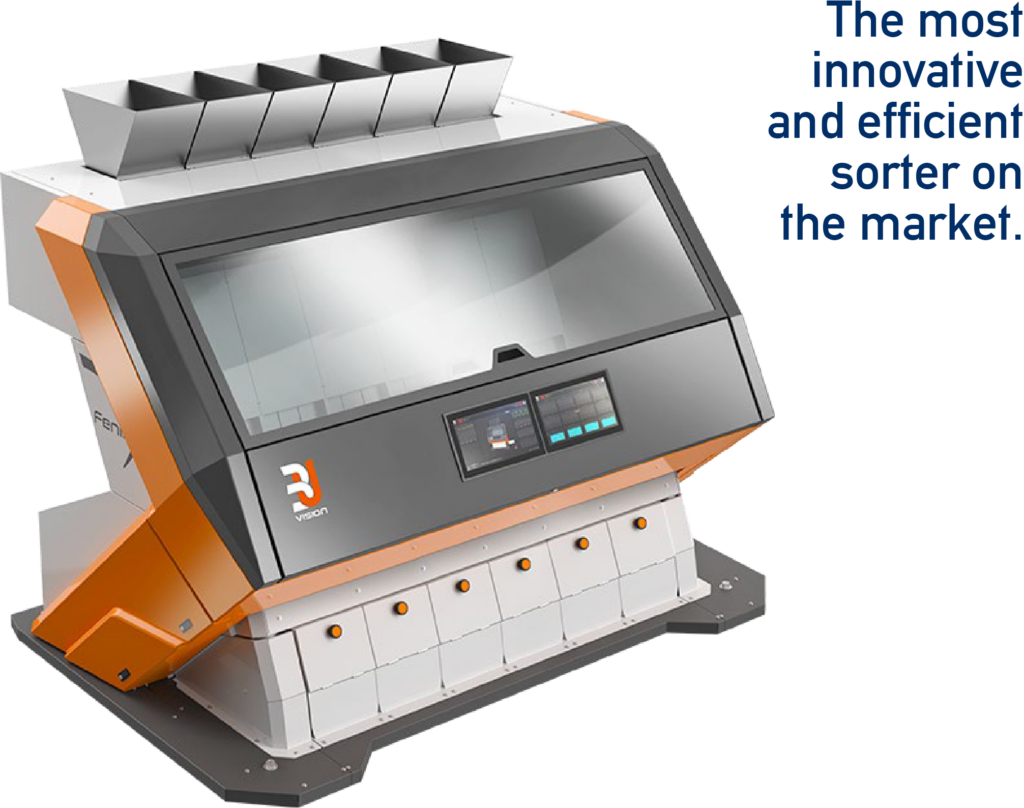

3U Vision Fenix

About the 3U Vision Fenix

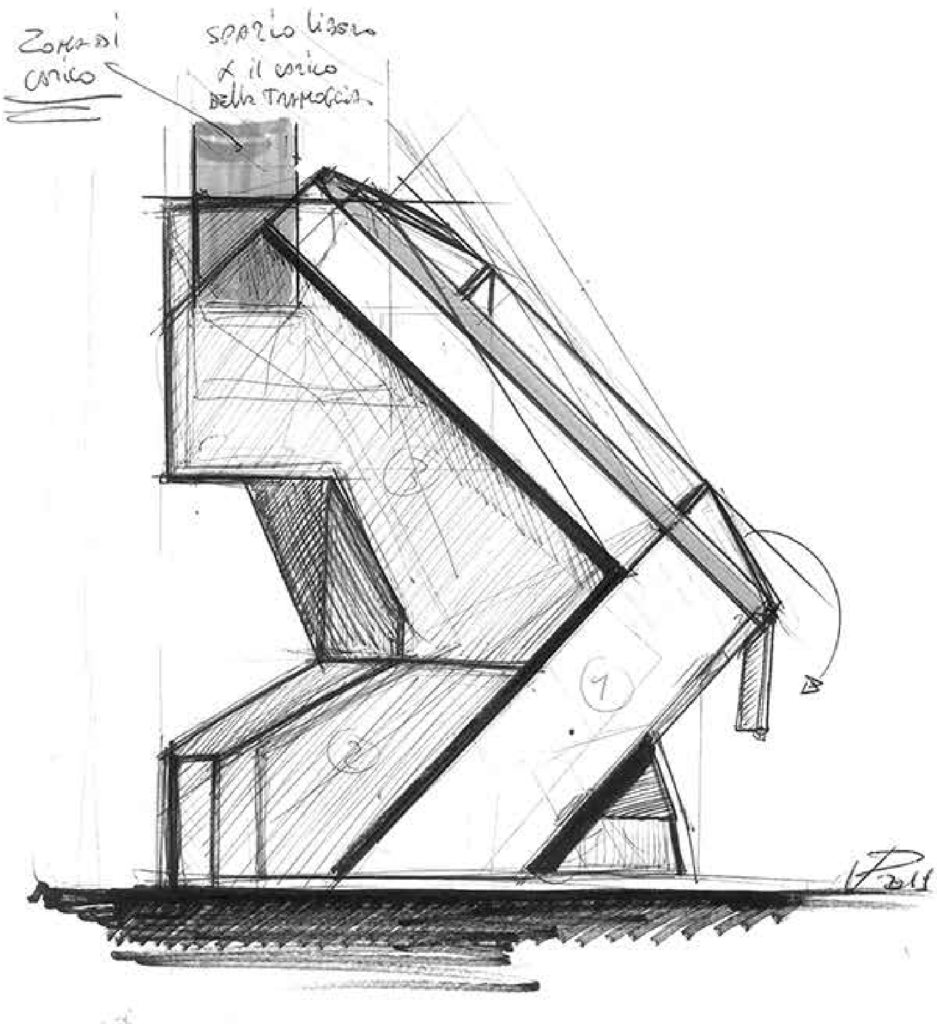

The 3U Vision Fenix optical sorter is the result of 40 years experience in vision systems. It uses the latest technologies and in some cases has been developed exclusively by 3U Vision.

The 3U Vision Fenix incorporates 4 wavelengths multispectral system as standard equipment, RGB and IR in the same 4K sensor. This innovative solution allows a completely aligned view. A real improvement detecting defects in similar coloured products but with different answers to infrared as foreign bodies, inorganic defects, etc. Furthermore, it allows a considerable cost reduction compared to the market standard with the use of two different cameras.

Specifications

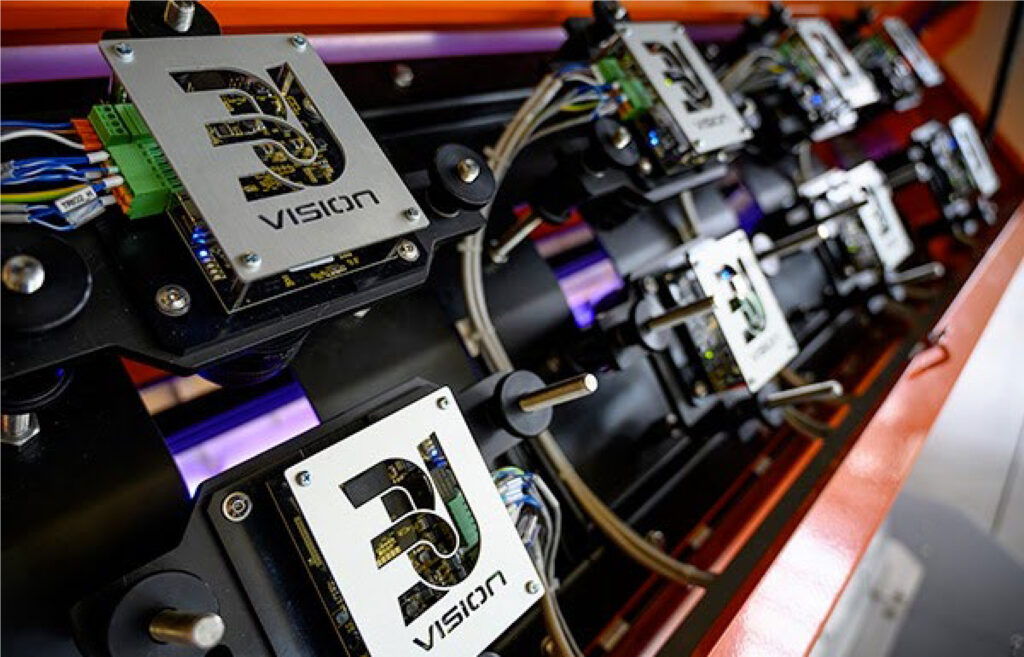

High resolution multispectral cameras SWIR (1024 pixel), up to 4 wavelengths. These cameras allow results which have previously been unreachable, until now. They recognise polymers, selecting shells and foreign bodies in dried fruits. They recognise where there are chemical differences even if not visible by the human eye.

Simultaneous use of RGB, SWIR and IR optical systems: up to 8 frequencies (the standard on the market for these sorters is usually not more than 4 frequencies).

Flat spectrum led (they reproduce the natural sunlight spectrum). State of the art full spectrum led, without low light areas typical of the standard white led. They allow to detect all the slightest colour shades.

State of the art Ev, 3.2mm pitch: with custom design and specification, they can reaches top values in duration and speed. They allow almost double the number of electrovalves in each chute. In this way, we increase the production speed, reduce the quantity of good quality product wrongly expelled. It will reject more concentrated product and allow a reduction the air consumption.

RISE-UP system: it allows to move the ejectors close the inspection line; halved distance compared to the other sorters on the market. It reduces the errors due to the different products fall speeds.

Multi wavelengths led with focusing lens, it focuses the light only on the right points and it allows to reach high illumination and low consumption.

Automatic air pressure regulator: it regulates automatically the pressure of the machine use according to the selected product and it allows to improve the selection, reducing both the quantity of reject and the air consumption.

Morphological analysis of the product: it extrapolates the statistical data of the product: average width, average height, percentage of wreckage, etc.

System of signals equalisation, in order to obtain the same results in each chutes of the machine.

Automatic control and equalisation of the vibrators speed, in order to have flat and uniform flows in all channels.

Dual display 15”: all the useful information for machine monitor, always visible thanks

to the two 15’’ touchscreen displays.

Find out more about the 3U Vision Fenix

Vanessa Schofield, a key member of the Tornum team with extensive technical knowledge, is the primary representative for 3U Vision.

Contact Vanessa – vanessa.schofield@tornum.com / 07477 509 516